Peel machining is one of the most versatile methods of manufacturing mechanical parts. Due to the possibilities offered by this technology, it is one of the pillars of the Company's business.

Wilhelm R&D successfully uses its own machine park containing manual and CNC machine tools to produce mechanical parts according to the contractor's documentation or for ongoing projects. In addition, the company offers consulting on improving the technological feasibility of prototype parts, a service for recreating damaged parts for which technical documentation is unavailable, and geometric surveying and building CAD models based on existing parts.

HAAS VF2 automated 3-axis milling center.

Working area:

Length of milling piece X = 762 mm,

Width of the milled part Y = 406 mm,

Height of the milled part Z = approx. 300 mm (501 mm)

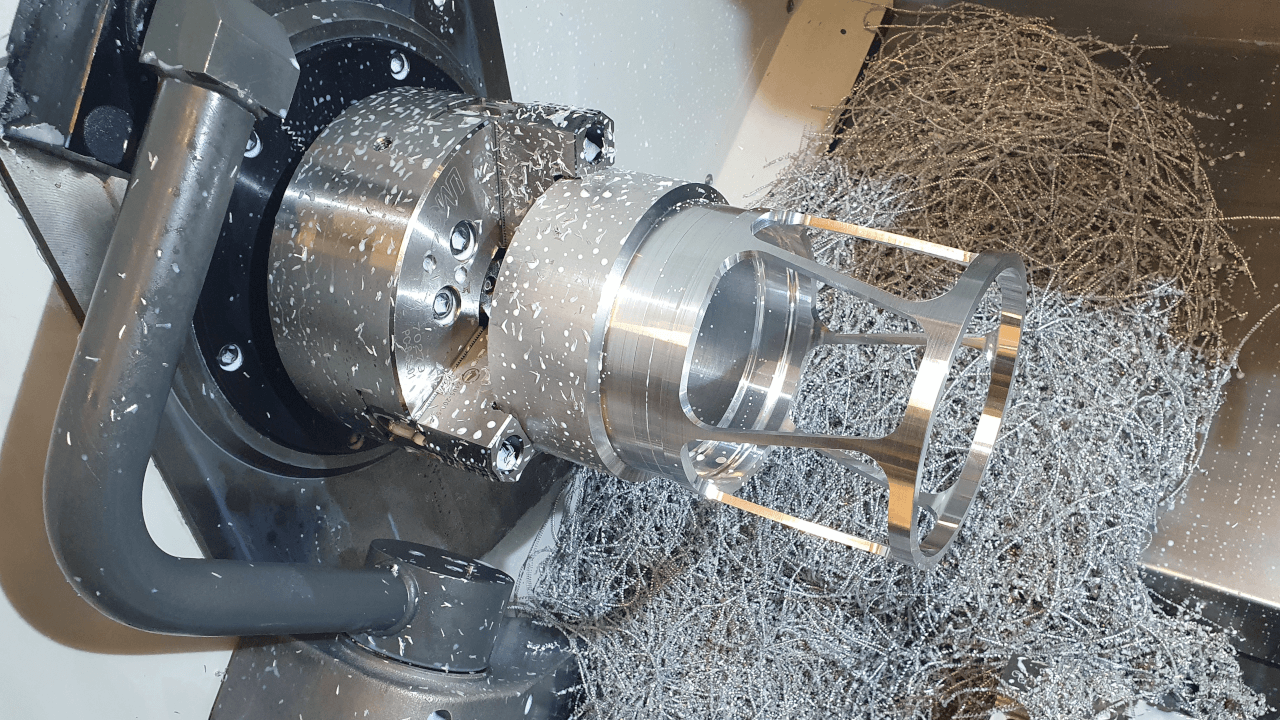

HAAS ST 20 Y automated 4-axis turning and milling center.

Working area:

Length of the turned part Z axis = approx. 450 mm (travel 571 mm)

Turning diameter X axis = approx. 320 mm (travel 213 mm)

Milling width Y axis +/- 50 mm

Auxiliary machines:

Manual drilling and milling machine with tilting quill - ZX50 C

Manual lathe machine - CQ6236KX1000

Watchmaker's lathe

MIG MAG welding stand

Station for welding with the TIG method

Workshop hydraulic press 30 T

Band saw - max. cutting diameter fi 30 mm

Hardening furnace - chamber dimensions 240 x 170 x 500 mm

CarlZeis Jena geometric measuring microscope

Rockwell hardness tester

Brinnel Vickers hardness tester.